How to choose the right contacts for your connector?

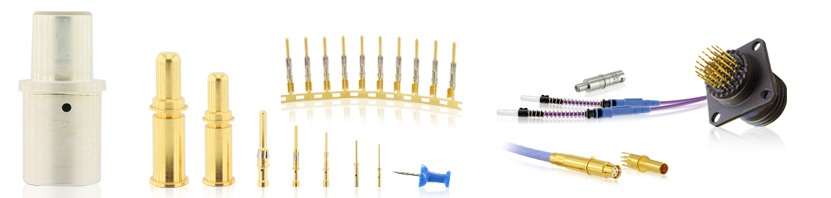

Contacts are the pins and sockets that establish the electrical connection when they come into ‘contact’. Some connectors are delivered with contacts, some without. Of the ones delivered with contacts, these might already be loaded or not. Typically, solder cup contacts and PC tail contacts are often preloaded, while crimp contacts are not, but it really depends on each product series, so it is important to understand which contacts are suitable for your application.

Selecting contacts for your connectors can be confusing as contacts come in a variety of shapes, sizes and types. This buyer guide walks you through the important elements to consider when choosing which ones will deliver the best possible connection for your application at the best price.

Electrical contacts

Let’s start by reviewing the 2 types of standard electrical contacts you’ll find:

Signal

Electrical signals are used to communicate information from a source to a destination. When the quantity of information is large, it will usually be referred to as data. Signals on the other hand usually communicate basic information in binary form (ex: ON or OFF), and are found in applications like sensors or buttons. Signal contacts are therefore usually small (#20, #16), since they don’t need to transfer much current and voltage (usually between a few mA to a few A).

Power

Power contacts on the other hand transfer voltage and current in order to operate components and equipment. For applications requiring small voltages, the contacts can be the same as signal contacts. However, larger or more energy-intensive applications will require larger sized contacts such as #12 or size #8. Industrial power contacts can deliver up to a few dozen Amps of current.

Reminder: for contacts and wires, smaller numbers represents larger sizes: i.e. size #8 is larger than size #20.

SOURIAU provides an extensive range of contacts including power and signal, but also fiber optic

CRITERIA FOR SELECTING CONTACTS

Now that we have a slightly clearer picture of what contacts are, let’s take a look at how to pick the right one for you. There are a few criteria that you need to look at before making your pick.

- Connector & layout (to determine contact size)

- Your wire size

- Contact type (machined, stamped & formed)

- Delivery option (bulk or on reel)

- Plating

- Termination type (solder, crimp, PC tail, wire wrap)

STEP 0 – YOUR SPECS

The very first element to consider when picking contacts is the amperage and voltage that is going to be running through your circuit. This will determine which connectors are available and consequently which contact sizes.

Remember to consider also the current carrying capacity of your connector and contacts. As electrical current goes through your connector, heat will be produced by the contacts, and the more contacts you have, the more heat the connector will be subjected to. This means that if your connector is going into a machine where the temperature will reach 120° C and its max operating temperature is 125°C, the heat produced by the contacts might subject the connector to a temperature above 125°C and consequently damage your system.

The connector layout will therefore be a key element to decide on. For contacts of the same size and capacity, increasing the number of them within your connector will increase the heat that they produce, so you will need to find the right balance between your electrical requirements and the current carrying capacity of the connector you are looking at. Each layout is also designed for dedicated contact sizes, and if you pick your layout first, it will determine which contact sizes can fit in it.

STEP 1 - WIRE SIZE

This is probably the most straightforward element. If you are looking to buy contacts, then you probably already have wires that will be inserted into the connector. Find out what size these wires are as this will determine which contact sizes you can choose from.

On the other end of the scale, AWG wire size 8 and 10 (8.36 & 5.26 mm² respectively) will only be able to have #8 contacts as all the other contacts will be too small.

Find our complete TRIM TRIO contact size table here: http://ipaper.ipapercms.dk/SOURIAU/UTSSeriesUS2015/?page=164

For information about our other contacts, please refer to our website: https://www.souriau.com

STEP 2 – CONTACT TYPE

Types of contact include stamped and formed as well as machined contacts. This choice will mainly depend on your personal preference and crimping equipment. Machined contacts are usually preferred for power applications or for low volume orders. They are usually also more heavy-duty and suitable for intensive usage. Stamped and formed contacts offer the ability to be fed into automated crimping machines making them more suitable for high volume production.

Certain industry standards, notably in aerospace and railway, require machined contacts.

STEP 3 - DELIVERY OPTIONS

Contacts can be delivered in different delivery formats, they can be packaged loose in bags, or loaded on a reel. While all options are possible, by default machined contacts will be packaged loose in bulk while stamped and formed contacts will be delivered on reels. What you choose here will primarily depend on your setup. Different types of automated or semi-automated crimping equipment may require you to receive your contacts in either option. Just note that generally, stamped and formed contacts mounted onto reels are designed to be fed into automatic crimping machines, and attempts to crimp them with hand tools can lead to quality issues.

Contacts packaged in bulk

STEP 4 – PLATING

The plating on contacts impacts the conductivity of the connection, as well as the durability of the contacts and so plays a key role in the choice. For smaller contacts, under 1A and 5mV (#20 and #16), the contacts will be plated with at least 0.4µm of gold. Gold has excellent conductivity and good lubricity properties, making it robust for numerous mating cycles or intensive use. It does have one disadvantage though, which is its high cost.

For slightly bigger contacts, a larger surface means a higher cost of plating. This explains why we usually find tin, which is a cheaper option that performs almost as well for static or low-vibration environments. For applications where the system will be subject to higher vibration or numerous mating cycles (100+), the option of gold flash plating is preferred to ensure a more reliable connection.

Finally for size #12 and #8 contacts, silver is the preferred option, providing the right balance between cost and high reliability performance.

To sum up, if you need to choose contacts for your connectors:

- Identify your AWG wire size to find which contacts are available

- Find out which connector and which layout you will be using

- Determine if you prefer stamped and formed or machined contacts based on your performance requirements and crimping setup

- Consider whether you want your contacts packaged in bulk or on a reel

- Select the best plating option for your application based on your performance requirements.

And of course, if you have any questions you can contact our technical and commercial teams at https://www.souriau.com/en-en/contact .